第四代造纸毛毯

三维多轴叠层底网毛毯

3D MULTIAXIAL LAMINATED BOM FELT

第三代造纸毛毯基网的经线和纬线都是成垂直状态,叠层基网在高线压的情况下,基网与 基网之间会相互嵌入,从而大大降低了毛毯的抗压性和容水空间,毛毯容易板结,持续脱水能 力较弱,使用寿命会缩短等。

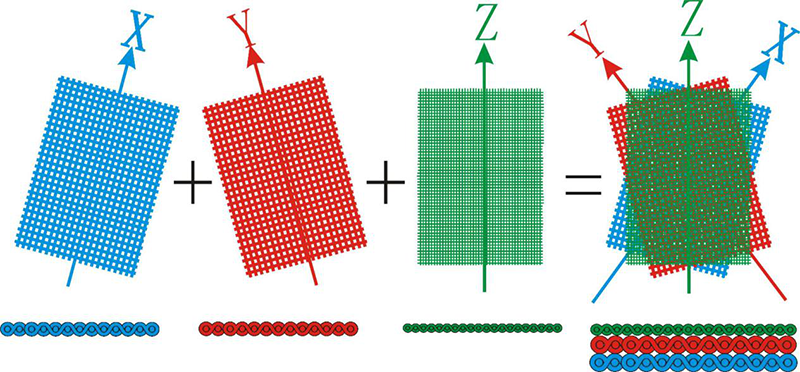

在第四代造纸毛毯中,三维多轴向叠层底网毛毯各层基网的经线与纬线不是呈传统的90度 交叉,而是呈特殊的不同角度。根据纸机的需要,毛毯的基网层可叠加成X+Y或X+Y+Z等多种 形式,这样各层基网的经纬线在重叠后没有被彼此压陷的可能,所以具有更高的耐高线压能 力,提速更快,汽耗更低。

此类系列毛毯抗压力可达1300KN/M,工作车速可达1500MPM, 毛毯克重可达 2000GSM。 具有结构稳定、抗压性能优越、持续脱水能力强、强度大、毯面平整、不易变 形、使用寿命长等特点。

The warp and weft lines of the base mesh in the third generation papermaking felt are all vertical.Under the condition of high line pressure,the mesh and the mesh will be embedded in each other,which greatly reduces the pressure resistance and water holding space of the felt.The felt is easy to harden,the ability ofcontinuous dehydration is weak,and the service life will be shortened.

In the fourth generation of BOM,the warp and weft of the 3D multi axial laminated BOM are not woven in a traditional 90 degree cross,but in a special angle.According to the needs of the paper machine,the mesh layer of the felt can be stacked into various forms such as X+YorX+Y+Z,so that the warp and weft lines of each layer of the mesh are not likely to be pressed into each other after overlapping,so it has higher resistance to highline pressure,faster accelerationand lower steam consumption.

The pressure resistance of this series of felts can reach 1300KN/M,the working speed can reach 1500MPM, and the base weight of felts can reach 2000GSM.The utility model has the advantages of stable structure, excellent compressive performance,strong continuous dehydration ability,high strength,flat felt surface,not easy to deform,long service life,etc.

|

|

|

基网重叠示意图 SCHEMATICDIAGRAM OF MESHOVERLAP |

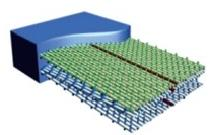

三维多轴向叠层底网造纸毛毯 3D MULTIAXIALLAMINATEDBOMFELT |

关键词:造纸毛毯 | 压榨毛毯

产品留言

0395-8662688

0395-8662688

在线留言

在线留言